Established in 2002, Skytech Group has consistently demonstrated its commitment to provide professional services within the semiconductor and related technology industries. Over the years, we have gained recognition by receiving verification from major global semiconductor wafer foundries and memory wafer manufacturers. This verification underscores our standing as an outstanding and qualified supplier, maintaining long-term partnerships with our esteemed clientele. The genesis of our company traces back to a group of seasoned semiconductor technology experts who joined forces. Beginning in 2002 with a single ceramic component for semiconductor equipment, we comprehended the intimate connection between semiconductor technology evolution and equipment capabilities. Our research and development efforts continue to evolve daily, paralleling the steady growth of our business.

Our services and component products in the components field encompass a wide spectrum, including thin film processing, etching processes, diffusion processes, grinding processes, measurement processes, photolithography processes, and automation equipment. While we emphasize the stability of our current technical products, we place even greater importance on the constant stream of technological innovation and service enhancements. By offering superior structural design, material refinement, and firmware integration, we contribute to elevate wafer production yields and decreased manufacturing costs. Consequently, the trust bestowed upon us by our clients continues to burgeon, positioning us as the preferred collaborative partner for Continuous Improvement Projects (CIP).

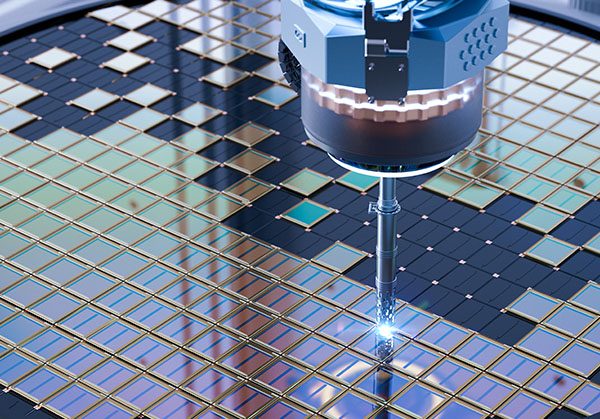

Skytech embarked on the development of its proprietary advanced semiconductor equipment brand in 2017. In the following year, it designed its first semiconductor wafer manufacturing equipment, the PVD machine called Nexda. In the same year, they also developed bonding machines of various sizes and de-bonding machines. The company continued to innovate and expand its product line, introducing the Atomila, an ALD (Atomic Layer Deposition) semiconductor manufacturing equipment in 2019. In 2020, Powder ALD was introduced, and by 2021, they successfully entered compound semiconductor equipment applications. In 2022, the development of PEALD was completed, and in 2023, they introduced etching equipment such as Descum and Plasma Polish, showing a commitment to continuously meeting market demands while diversifying their semiconductor equipment development and manufacturing.